Smart factory serving the brand

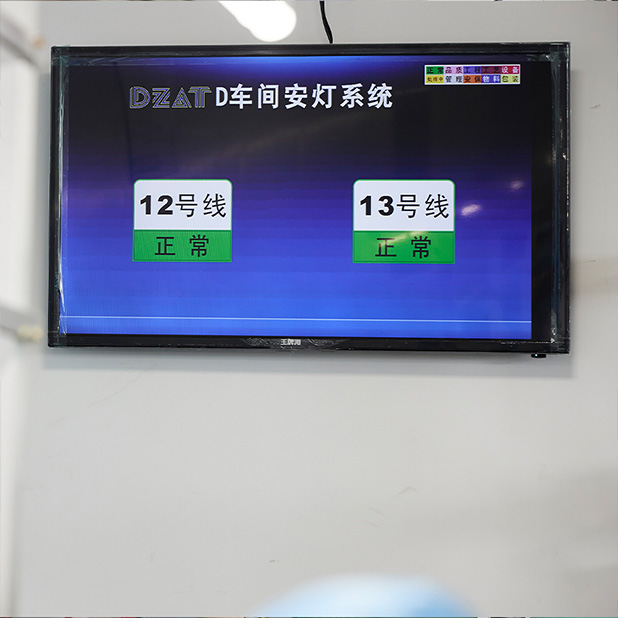

Dzat Dust-free workshop is composed of dust-free workshop, dust-free corridor and material elimination room. We using air-conditioned FFU dust extraction and ventilation system, independent exhaust gas extraction system, call big data system, production Kan-ban system and other systems as our core system. We also combined with man-goods separation control, functional workshop control, material processing control and other methods. Not only to achieve GMP medical level dust-free workshop, but also to achieve this as the core of the operating system.

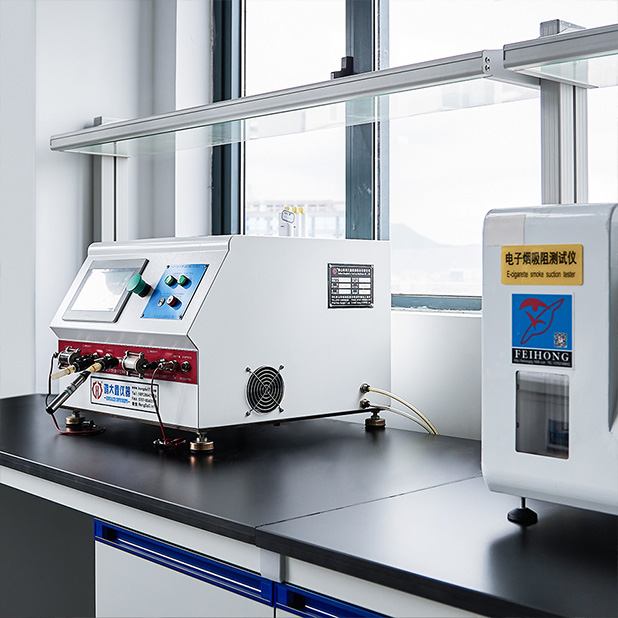

The laboratory is composed of comprehensive atomizer experimental equipment, R&D equipment, and testing system. Using 3D printing equipment can not only achieve independent R&D and testing of atomizer security level, but also comply with national standards (GB 41700-2022), TPD and other multinational standards. We combined with the test system of DZAT and completed reliability test quickly.